Professional solutions assist various industries

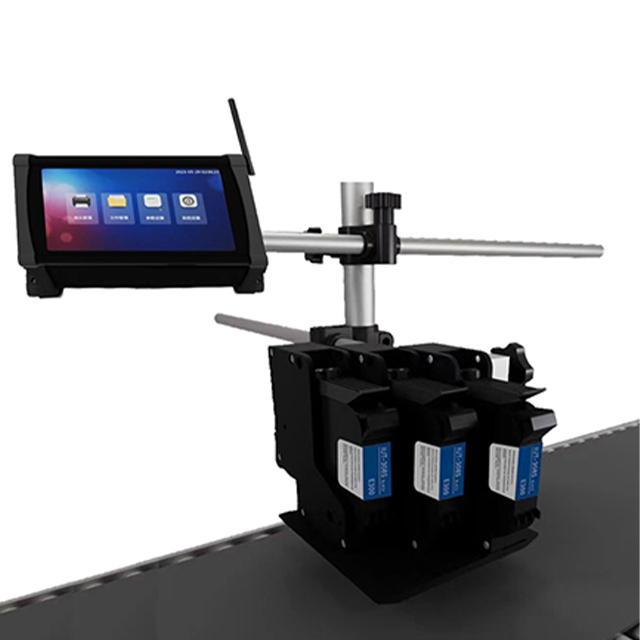

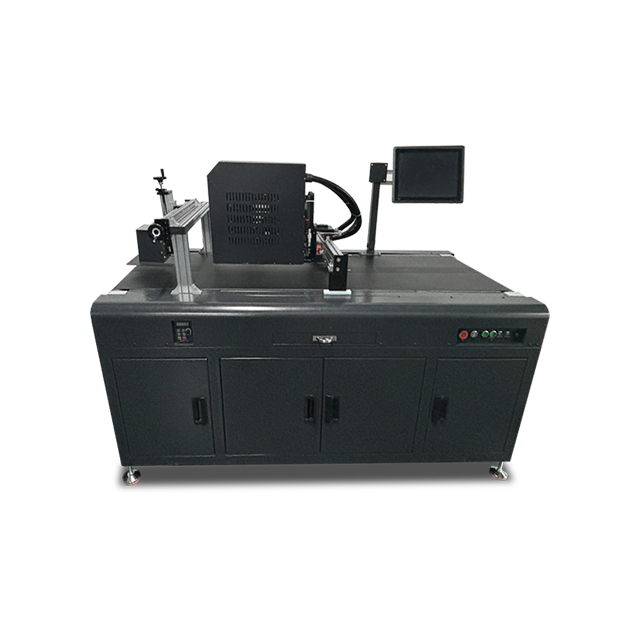

Carton coding machine|Cargo box coding machine

As a precision machine equipment in industry, cardboard box inkjet printers are widely used for printing on daily cardboard boxes, including high-resolution inkjet printers and UV inkjet printers. The specific model to be used depends on the printing needs of enterprise users. Next, we will analyze in detail the functions and applications of common inkjet printers in carton printing.

Packaging film printer

Labeling machine with printing PVC film, aluminum foil bags, plastic packaging bags, barcode continuous printing

Woven bag inkjet printer | inkjet printer equipment manufacturer

MASIJET small character coding machine is entering the flour mill market. The fully automatic small character coding machine has inherent advantages in the automation level of the flour mill production line. No matter how the product packaging is or how complex the production line is, it is not a problem for CIJ coding machine.

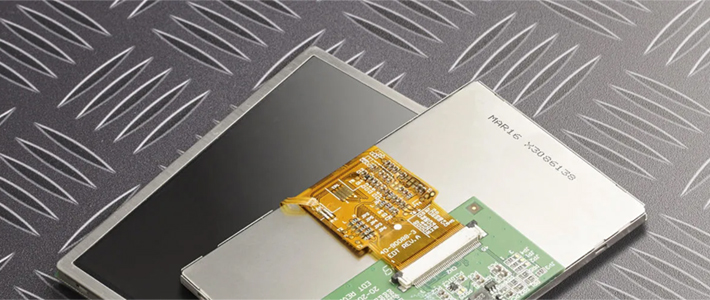

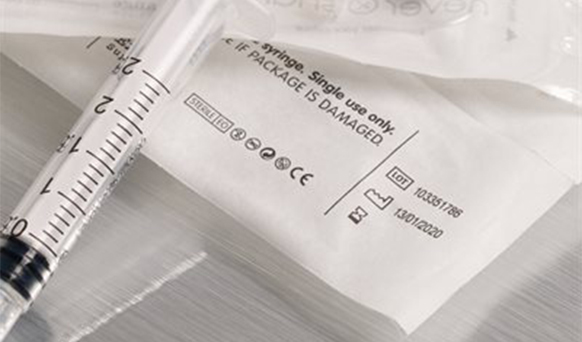

Medical equipment/QR code inkjet printer

UDI (Unique Device Identification) consists of Fixed Device Identification (DI) and Variable Production Identification (PI). UDI must provide both human readable (plain text) and machine-readable formats, with the latter utilizing Automatic Identification and Data Collection (AIDC) technology

Global pharmaceutical packaging coding identification

Laser coding machines are gradually entering the pharmaceutical box industry, and laser coding machines are an effective method of directly creating secure markings on the surface of bottles or bottle caps. Laser marking technology uses small mirrors or galvanometers to guide the laser beam, which can directly engrave or burn the ink surface on the label on the plastic bottle.

Mask coding machine

Mask coding machine, mask coding solution (combined with fully automatic mask machine, laminating machine, conveyor belt) Hongma Chuang is an equipment provider specializing in continuous inkjet, laser coding, and outer box coding. Since its establishment, relying on a solid technological foundation, we have continuously utilized innovative technologies to help organizations in various regions improve productivity and significantly reduce procurement costs.

QR code inkjet printer - reliable quality - easy to operate

QR code, also known as QR code, is a popular encoding method on mobile devices in recent years. It can store more information and represent more data types than traditional Bar Code barcodes.

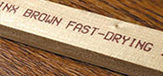

Cable industry coding machine

The performance of coding solutions in the wire and cable industry needs to match the actual production process. The shutdown of the inkjet printer will interrupt the extrusion process, resulting in high costs of shutdown, rework, and scrapping. In addition, poor coding contrast or quality and ink transfer printing can also reduce product quality.

OUR ADVANTAGES

OBTAIN CERTIFICATE

【WeChat】

Herb Hong manager +86 136-3142-6877

Echo Chao Sales +86 186-2078-5726

Morry sales +86 189-2873-5169

136-3142-6877

136-3142-6877